10 – 14 November 2024

Join us at C&P 2024 as we navigate all things corrosion.

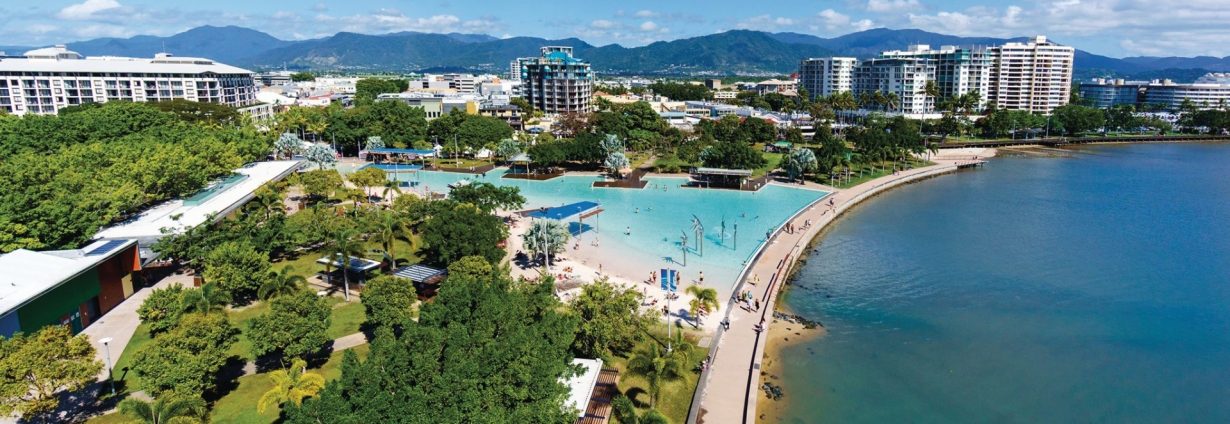

Cairns is a unique city located on the north-east coast of Australia, and is home to the world heritage-listed Great Barrier Reef and wet tropics rainforests.

10-13 November – Cairns Convention Centre (Main Conference)

14 November – Applicator Day (Venue TBC)

What’s happening in Cairns?

The Australian Government is delivering significant support for Cairns under the Local Roads and Community Infrastructure Program. This includes $13.9 million across all four phases supporting Cairns Regional Council to deliver priority local road and community infrastructure projects, creating jobs and long-lasting benefits for the region.

$9.1 million is also being delivered from 2019-20 to 2023-24 under the Roads for Recovery program, which supports construction and maintenance of local road infrastructure assets. This is in addition to over $900,000 for projects under the Black Spot Program, tackling high-risk road crash sites.

The Cairns Marine Precinct, which the Australian Government has committed $180 million towards, is on track to begin later this year. This is expected to create 460 construction jobs while delivering a 5,000-tonne ship-lift, three ship hardstand areas and other components – which will support bigger ships and contracts coming in, underpinning more revenue and local jobs.

The Australian Government has also committed $50 million for the construction of a new, purpose-built Cairns CBD campus for the Central Queensland University, to accommodate a greater number of students and diversify the region’s higher education options.

Through the Investing in Our Communities Program opened earlier this year, the government is delivering on its election commitments to Cairns, which include a $1.7 million commitment for the Cairns Cricket Club Association and $290,000 in commitments for the Cairns Regional Council.